handle backlog and inventory problems more efficiently than do kanban-trained workers. respond to changes in demand quickly and efficiently. Specialized Workers can be useful in other than long-term planning works.ĭ. are useful only when long-term planning becomes possible. play a more limited role in the kanban system.Ĭ. No where in passage, it is stated as such.ī. require more training than employees under the kanban system.

It can be inferred from the passage that specialized workersĪ. challenge the theory that kanban workers are less efficient in a global market.ģ. support the thesis that predictable demand may encourage an otherwise less efficient practice.Į. argue against the reintroduction of the specialized worker.ĭ. provide an example of how rapid response to global demands can improve productivity.Ĭ. prove the argument that kanban workers are more efficient than specialized workers.ī. Since kanban has made Japanese automobile so efficient and responsive that, the industry can plan it's demand up to next 10 months,and It does not require the kanban practice anymore.Ī. The 3rd passage tells us how the Process of Kanban has caused it's own demise. The author cites the productivity increase of 27 percent in order to was the primary reason for the lack of success of the Japanese automobile industry in the 1980s. rested on the shortened two-week time-frame of the kanban system. stemmed from the production department’s need to schedule and the marketing department’s need to respond quickly.

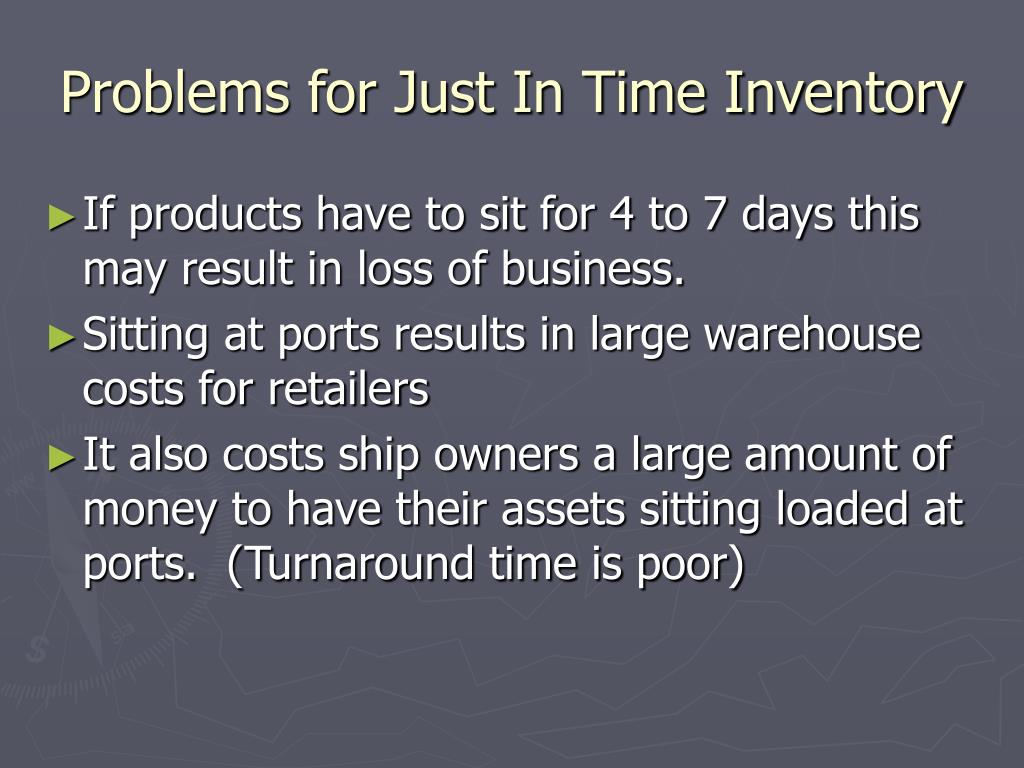

Carefully Constructed to get you hooked.Production Employees get trained to adapt to the changes suggested by Marketing Department)Ĭ. led to the training of marketing employees in the kanban system, enabling them to shift rapidly to any job in the factory. resulted from both departments’ failure to communicate concerning backlogs, inventories, and outputs. It can be inferred from the passage that the conflict between marketing departments and production departmentsĪnswer: Marketing Department adapts to the changes in the market,while Production Department deals with planned(as it informs other departments of things it needs 2 weeks before 2 weeks) activities.Ī. Production schedules up to ten months in advanceĪnd, as a result, workers no longer need to jumpįrom position to position. (25) Requests for automobiles are increasing at suchĪ steady rate that managers can now determine With a large and predictable global demand. Mobile manufacturers find themselves confronted Byīeing so efficient and responsive, Japanese auto. Job in the factory, as needed, thus diminishingīut kanban may have caused its own demise. However, the manufacturers had to train productionĮmployees to shift on a moment's notice to any (15) other departments of its backlogs, inventoriesĪnd outputs. Need to plan their production on a two- week schedule Marketingĭepartments need to respond quickly to changingĬustomer wants and needs production departments The conflict between most marketing and production Planned schedules of production and have led toĪ reintroduction of an old friend: the specialized (5) demands of international trade reward more Japanese automobile industry's success in theġ980s, may be falling out of favor. Inventory control), credited for much of the The Japanese system of kanban (just-in-time

0 kommentar(er)

0 kommentar(er)